KamerMaker starts 3d printing canal house. PBS reports on 3d printing dinner for two and 3d p. Most important tools you need for building and usi. Exoskeleton with 3d printed parts helping disabled. Mark One carbon fiber 3d printer update and team m. Lulzbot factory tour and Open Hardware business model. EyewearKit for your 3d printed eyeglasses frames. Upgrading Sieg Mini CNC into 3d printer. BigRep 3d printer with HUGE printvolume. ECV One 3d printer by E-Crew Vis from France. mUVe open source low cost stereolithography 3d pri. Bre Pettis interview by Singularity 1 on 1. Big Builder tall 3D printer from Netherlands. MX3D Metal supportless multiaxis 3d printing. 3d printable Google Glass adapter for any frame. Hot to calibrate extruder on Cerberus Pup and set. How to make PLA plastics flexible with Carburetor. Sketchfab - 3d model sharing and embedding (Update. Software tool chain for everyday 3d printing by St. mUVe developed improved Marlin firmware. OpenKnit - open source knitting machine. From DIY 3d printing history 3 - CNN interview wit. Dell and conflicting marketing messages in 3d prin. AJ TV report on printing replacment human skin for. How to create model for 3d printing from CT or MRI.

KamerMaker starts 3d printing canal house. PBS reports on 3d printing dinner for two and 3d p. Most important tools you need for building and usi. Exoskeleton with 3d printed parts helping disabled. Mark One carbon fiber 3d printer update and team m. Lulzbot factory tour and Open Hardware business model. EyewearKit for your 3d printed eyeglasses frames. Upgrading Sieg Mini CNC into 3d printer. BigRep 3d printer with HUGE printvolume. ECV One 3d printer by E-Crew Vis from France. mUVe open source low cost stereolithography 3d pri. Bre Pettis interview by Singularity 1 on 1. Big Builder tall 3D printer from Netherlands. MX3D Metal supportless multiaxis 3d printing. 3d printable Google Glass adapter for any frame. Hot to calibrate extruder on Cerberus Pup and set. How to make PLA plastics flexible with Carburetor. Sketchfab - 3d model sharing and embedding (Update. Software tool chain for everyday 3d printing by St. mUVe developed improved Marlin firmware. OpenKnit - open source knitting machine. From DIY 3d printing history 3 - CNN interview wit. Dell and conflicting marketing messages in 3d prin. AJ TV report on printing replacment human skin for. How to create model for 3d printing from CT or MRI.

3D Printing curriculum for your school classroom b.INventOne 3d printer by MakerDreams from Italy.

BotBQ open source barbecue extruder for your 3d pr.You can also check out this Matsuura Lumex machine with similar approach:

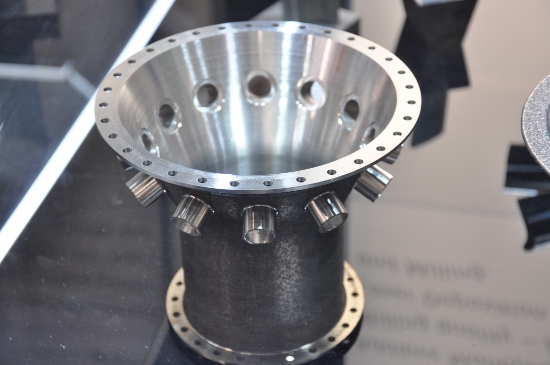

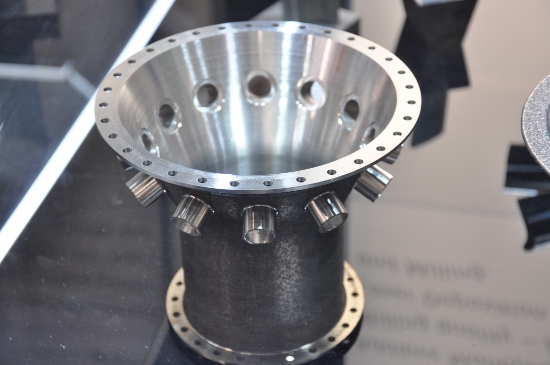

LASERSOFT 3D texturing software package for the laser structuring of 3D surfaces: from Bitmap to the finished texture.Environmentally-friendly methods that do not require the use of chemicals.Unlimited design possibilities for geometricallydefined surface textures in free-form surfaces.Change over time from milling to laser operation only approx.Full fledged 5-axis milling machine from DECKEL MAHO in the rigid monoBLOCK® / duoBLOCK® Series flexible integration of a laser head via the HSK interface.5-axis: milling and laser texturing of plastic injection moulds on one machine in one setup.The printed part is probably lighter and stronger since its laser is creating more carbon bonds. The turbine housing just grows in front of you. When you see this machine at work, you see the future of production.

0 kommentar(er)

0 kommentar(er)